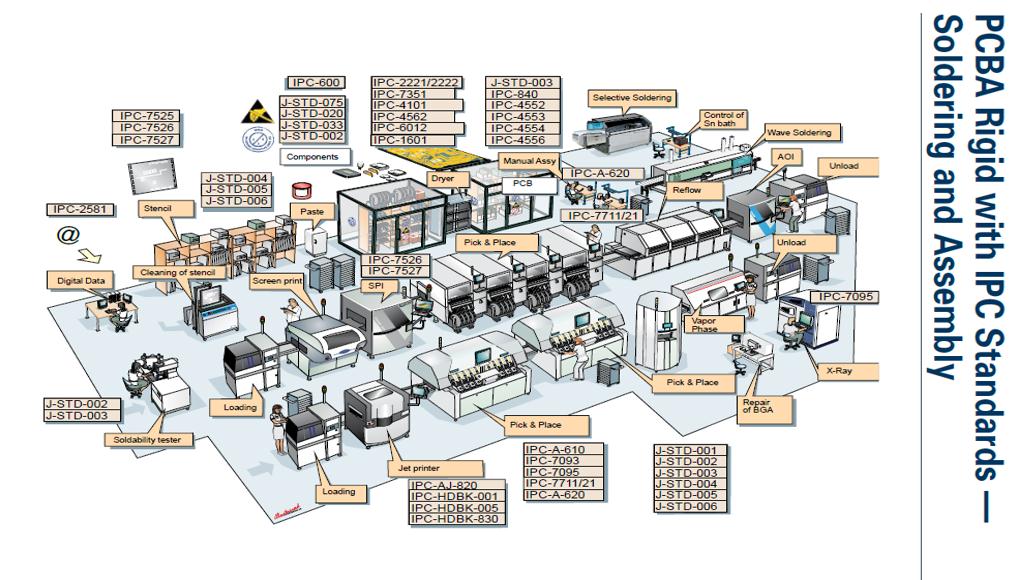

These are morden machines and technologies that contribute to development of global electronics industry as well as the success of the world's leading electronics corporations. Referring to this we have to mention the contribution of welding technology surface components SMT (Surface Mount Technology).

Surface-mount technology (SMT) is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced the through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

SMT technology is widely used in all civil, medical, defense and space technology electronics... Depending on the application in different fields, SMT technology processes require different complexity. In civil products, SMT technology is applied in different production areas, we can see such as: Computer board, Phone board, TV board, Memory & storage devices. ..

SMT technology is currently widely used in manufacturing and assembling electronic equipment such as SamSung, LG, Apple, Foxconn... with the following advantages:

+ Minimize time and cost compared to old technologies (Throught Hole Technology) due to reduced time at the drilling stage and installation of components into the hole.

+ Reduce the size of PCB electronic circuits due to the ability to install small sized components, currently the smallest component size that SMT devices can install is: Length 0.1mm x Width 0.1mm .

+ Install many electronic components on a PCB circuit compared to the old technology

+ Install components on both sides of a PCB circuit

+ Electromagnetic compatibility (EMC) performance is better than the old technology

+ Low resistance and inductance in the welds

+ High level of specialization in technology processes reaches 100%

+ High degree of automation. At some stages of the current assembly line, it is possible to achieve a complete level of automation.

In Da Nang, DITP is implementing the SMT high-tech electronics manufacturing and assembly factory project, which creates the foundation for high-tech electronics manufacturing and precision mechanics and contributes to promote the development of supporting industries in Vietnam.